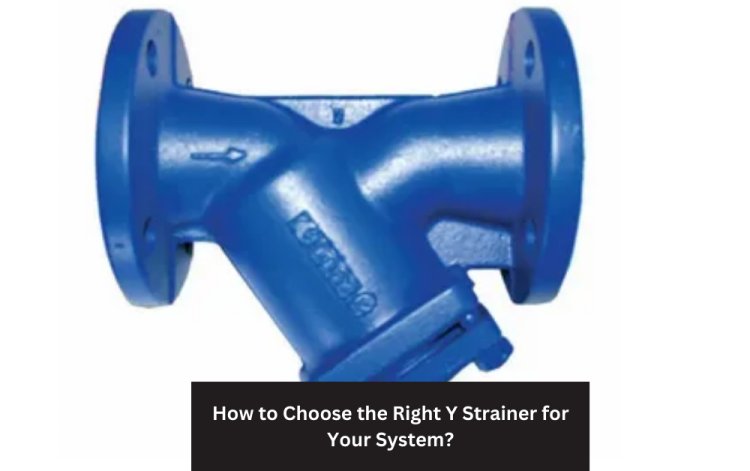

How to Choose the Right Y Strainer for Your System?

Understanding the Role of a Y Strainer in Fluid Systems

A Y strainer is a critical component in fluid handling systems, designed to filter out debris and contaminants from liquid or gas flow. It helps protect pipelines, valves, pumps, and other critical equipment from damage caused by foreign particles. Whether used in industrial, commercial, or residential applications, selecting the right Y strainer ensures efficiency, longevity, and cost-effectiveness in your system.

Key Factors to Consider When Choosing a Y Strainer

System Compatibility and Application

Before selecting a Y strainer, it is essential to analyze the system requirements, including the type of fluid, pressure, temperature, and flow rate. Different industries, such as water treatment, chemical processing, HVAC, and oil and gas, require specific strainer materials and designs to suit operational demands.

Material Selection for Durability and Performance

Y strainers are made from various materials, each suited for different applications:

- Stainless Steel – Best for corrosive environments and high-pressure systems.

- Cast Iron – Commonly used in water and low-pressure applications.

- Bronze – Ideal for marine and potable water applications.

- Carbon Steel – Suitable for high-temperature and industrial applications.

The choice of material directly impacts the longevity and efficiency of the strainer, making it essential to select one that aligns with the fluid type and system conditions.

Note:- Y Strainer for Improved System Performance Industrial pipelines were safeguarded using Y Strainer, which effectively filtered out solid particles, preventing damage to critical equipment. This reliable solution minimized downtime and increased efficiency. Upgrade your filtration system with Sensor Tech UAE.

Sizing and Mesh Selection for Optimal Filtration

Choosing the Right Strainer Size

Selecting the correct strainer size is crucial for maintaining flow efficiency without causing pressure drops. The strainer size should match the pipe size to ensure smooth operation and minimal resistance to flow.

Understanding Mesh and Perforation Size

The filtration capacity of a Y strainer is determined by the mesh or perforation size of the straining element. Some key considerations include:

- Fine Mesh (High Filtration) – Used for removing tiny particles in sensitive applications like pharmaceutical and food processing.

- Coarse Mesh (Low Filtration) – Suitable for applications where larger debris needs to be filtered out without affecting flow rate.

- Perforated Screens – Used in applications requiring structural durability and where large debris is expected.

Selecting the right mesh ensures effective filtration while preventing excessive clogging that may lead to maintenance challenges.

Pressure and Flow Considerations

Evaluating Pressure Drop and Flow Rate

A Y strainer introduces some level of pressure drop in the system. It is essential to ensure that the selected strainer does not cause a significant reduction in flow rate. The pressure drop depends on factors such as:

- The strainer’s size and design

- The level of debris accumulation

- The mesh size and perforation pattern

Using a properly sized strainer minimizes pressure losses while maintaining efficient filtration.

Understanding Blow-Off and Drainage Options

Some Y strainers come with blow-off valves or drainage ports, which allow for easy removal of debris without disassembling the unit. This feature is particularly useful in systems requiring frequent cleaning or maintenance.

Installation and Maintenance Considerations

Proper Installation Orientation

A Y strainer should be installed correctly to optimize its performance. It is usually installed with the strainer leg pointing downward to allow effective debris collection and drainage. Some key installation guidelines include:

- Horizontal Installation – Common in liquid systems where easy debris removal is needed.

- Vertical Installation – Used in gas or steam applications, ensuring proper filtration without compromising flow.

Maintenance Requirements and Cleaning Frequency

Regular maintenance is essential to ensure optimal performance and avoid clogging. Cleaning frequency depends on the amount of debris in the system and the strainer’s mesh size. To simplify maintenance, choose a Y strainer with an accessible cover or blow-down valve for quick cleaning.

Industry-Specific Y Strainer Applications

Water and Wastewater Treatment

Y strainers are used in water filtration systems to remove sediment, dirt, and organic materials, preventing blockages in pipelines and pumps.

Oil and Gas Industry

These strainers protect sensitive equipment in oil refineries and natural gas processing plants by filtering out solid contaminants from fuel and gas streams.

HVAC and Cooling Systems

In HVAC systems, Y strainers prevent debris from clogging heating and cooling components, improving efficiency and reducing maintenance costs.

Chemical and Pharmaceutical Processing

These industries require Y strainers with high-grade materials like stainless steel to withstand aggressive chemicals while maintaining high-purity standards.

Conclusion

Choosing the right Y strainer for your system involves considering material compatibility, sizing, mesh selection, pressure drop, and maintenance requirements. By selecting a Y strainer suited to your specific application, you can enhance system efficiency, protect critical components, and reduce operational costs. Proper installation and regular maintenance further ensure optimal performance and longevity of the strainer.

Understanding these factors will help in making an informed decision, ensuring that your system operates smoothly with minimal disruptions.

For More Isightful Articles Related To This Topic, Feel Free To Visit: memphisnewspress

What's Your Reaction?

.jpg)